- Home /

- Page

Our Services

EMBROIDERY

Embroidery is sewing design, type or logo onto garment with special thread. It gives garments a high perceived value and works very well on fleece and heavier weight garments

HEAT TRANSFER

Heat transfer involves combining heat and pressure to transfer images into garments. This is great option for detailed prints, customization, shorter runs and quick turnaround times.

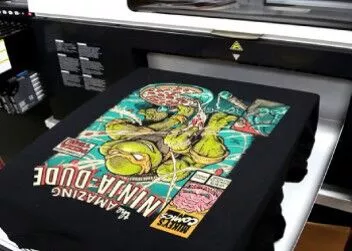

DIRECT TO GARMENT

Utilizes specialized ink jet technology to print water-based CMYK+ white-ink directly on garments. Ideal for projects with short turnaround times. Work on both light and dark garments.

SUMBLIMATION

This process utilizes heat-sensitive inks to create long-lasting, full color, photo quality reproductions of digital image. Sublimation is well suited for 100% polyester garments.

SCREEN PRINT

A technique that uses stencils and ink to create designs on garments. It is the most economical method of producing large quantities that involve cotton or cotton-blend garments.

FOIL PRINTING

It combines heat and pressure to transfer foil to a garment. Foils come in many colors and patterns and create dramatic accents or overall designs on all fabric colors and weights.

PUFF PRINT LETTERING

A method for creating a 3D design by screen printing with an ink containing a unique foaming agent or puff addictive that expands when heated. Ideal for simple design.

HOT SPLIT TRANSFER PRINTING

Combines heat and pressure to transfer images to garments. Most of the ink melts into the fabric to create a softer, lighter feeling print. Great for customization and shorter runs.

APPLIQUE AND EMBROIDERY

Sewing to a laser cut applique onto a garment and then embellishing it with emroidery adds dimension and detail to your garment. Ideal for heavier weight garments such as fleece

GLITTER PRINTING

A special clear glitter topcoat is screen printed on top of the colored design to add shine and impact to your design. This technique can work on all colors and weights of fabrics.

REFLECTIVE PRINTING

Small glass beads in the carrier base of reflective inks cause any bright light to reflect off the paint. This technique works best on larger print areas with simple designs.

DISCHARGE PRINTING

Using this two-step screen printing process helps you achieve the brightest possible colors on garment. It works by printing transparent neon in on top of a white opaque base.

NEON COLORS

Using this two-step screen printing process helps you achieve the brightest possible colors on garment. It works by printing transparent neon in on top of a white opaque base.

DISTRESSED AND CLEAR INK

Distressed printing gives screen prints an intentionally weathered look. Clear inks can be used to add a glossy shine or dimension to a design.

MIXED TECHNIQUES

Employs more than one technique to achieve the desired result. For example, combine screen printing and embroidery with a shiny applique for garment and with a higher perceived value.

LASER ENGRAVING

Laser engraving is the practice of using lasers to engrave or mark an object. Laser engraving mostly works with metal or wood surface and it is the most durable branding option.

EMBOSSING / DEBOSSING

Distressed printing gives screen prints an intentionally weathered look. Clear inks can be used to add a glossy shine or dimension to a design.

UV PRINT ON PRODUCTS

UV Print technology has become more common and therefore it is cost effective now. UV Print allow you to print crisp text and vibrant, full-color images using UV inks on wood, stainless steel, ceramic products, plastics, aluminum and more.